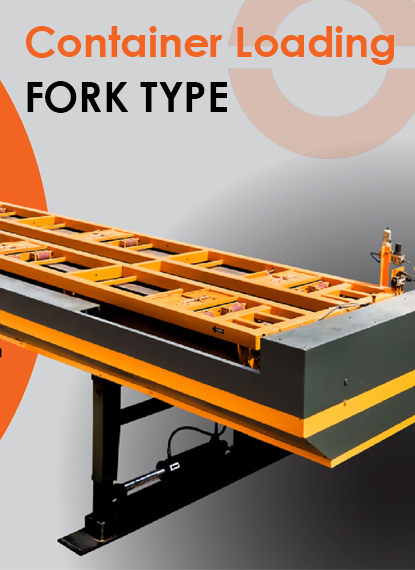

The Fork Type Container Loading-Unloading System is a highly efficient and versatile material handling solution designed for industries requiring fast, safe, and precise loading of goods into shipping containers. Built with a durable fork mechanism, this system is ideal for managing heavy, bulky, or palletized loads. It ensures smooth operation, reduces manual labor, and optimizes container space utilization.

Manufactured using robust, high-quality materials, the system is built to withstand heavy industrial use while maintaining reliability over time. Its design focuses on user convenience and operational efficiency, making it a practical choice for various sectors, including logistics, manufacturing, warehousing, and distribution. The system can handle a wide range of goods, from machinery and equipment to palletized food products, agricultural produce, and retail goods.

The Fork Type Container Loading-Unloading System is equipped with advanced technology to ensure stability, minimize the risk of accidents, and provide precise control over the loading process. Its compact yet powerful structure makes it an indispensable tool for businesses looking to optimize their container loading operations.

Handles up to 20-30 tons of cargo efficiently, which is perfect for heavy-duty operations.

It speeds up loading and unloading processes, allowing for faster shipment turnaround times.

Minimizes the need for manual labor, lowering costs and improving operational productivity.

Provides secure handling, reducing product damage risks and enhancing workplace safety.

Optimizes container space usage, enabling higher load capacity and saving transport costs.

Suitable for handling diverse goods like pallets, crates, and heavy machinery across industries.

Enhance functionality with additional equipments like night lighting, wheel blocking for trucks, and many accessories for a seamless loading experience.

*Power Inlet Range E.g. 200V-600V, 63A (According to the local requirements)

A container loading-unloading system enhances efficiency, reduces labor costs, and ensures safe handling of goods. Designed for heavy-duty operations, it optimizes container space, speeds up loading processes, and minimizes product damage, making it an ideal solution for industries requiring reliable and precise cargo management.